Climate Resilience

Sahamitr Pressure Container PLC recognizes the significance of climate change, a global challenge that necessitates collective efforts to reduce greenhouse gas emissions. Therefore, the company is committed to conducting its business with environmental responsibility and prioritizes the reduction of greenhouse gas emissions.

Potential Emerging Risks Affecting

the Company's Business Operations

Risk from Climate Change

Climate change poses a significant challenge to the company’s business operations. The world is currently placing great emphasis on preparing for this situation. Failure to prepare for the potential impacts could result in the loss of life and assets. One major issue is global warming, primarily caused by the release of greenhouse gas emissions into the global atmosphere. These emissions predominantly stem from vehicle engines, agricultural activities, coal usage, and industrial factory chimneys, leading to additional pollution problems such as PM2.5 air pollution. These pollutants have profound effects on the economy, society, and the environment.

Consequently, there is a societal push to reduce pollution and establish targets for reducing carbon emissions in both the public and private sectors. This is achieved through the implementation of laws, regulations, and rules related to greenhouse gas control. Various mechanisms, including carbon taxation and the use of carbon tax as a tool to incentivize carbon emission reductions through the Carbon Border Adjustment Mechanism (CBAM), are being employed. Additionally, there is a growing promotion of renewable energy usage to support clean and environmentally friendly energy sources. In light of these measures, the company’s business plan must be adjusted to align with the transition toward a low-carbon society.

SMPC has consistently conducted business operations with a strong commitment to environmental conservation. The company has implemented the ISO 14001:2015 — Environmental Management Systems throughout its organization. Environmental policies have been established, and activities and projects have been organized to raise awareness and prioritize the environment among employees. Digital systems have been introduced to reduce natural resource consumption. In addition to minimizing waste generation and pollution, the company has developed production processes aimed at reducing environmental impact. For instance, the utilization of a wet scrubber system prevents the emission of fumes and dust into the air, thereby safeguarding the environment. Creating green areas by planting trees along the perimeter fence is another initiative undertaken by the company. Furthermore, the company treats and recycles 100% of the water used in its production processes.

Recognizing the global challenge of climate change, the company is committed to conducting its business operations with environmental responsibility. It has joined the World LPG Association (WLPGA), which aims to promote the consumption of liquefied petroleum gas and reduce the usage of firewood, a major contributor to global warming. Moreover, the company has established a dedicated team to manage the organization’s carbon footprint. This team sets goals and guidelines for reducing greenhouse gas emissions. To reduce greenhouse gas emissions, the company has implemented various measures. For example, it focuses on minimizing air leakage from the general compressed air system in the factory, replacing inefficient air compressors, improving thermal insulation of gas cylinder furnace walls and doors, reducing paper usage, minimizing electricity consumption, and utilizing renewable energy through a solar power system installed on the factory roof (Solar Rooftop). These efforts contribute to the reduction of greenhouse gas emissions and support sustainable environmental protection.

Carbon Footprint Management Approaches

The company’s Board of Directors and senior executives have responsibilities in establishing and supervising the carbon footprint management team. This team is responsible for setting goals and guidelines aimed at reducing greenhouse gas emissions in accordance with the company’s carbon footprint management method. The company’s approach to climate change management includes the following:

- Conducting an analysis of the environmental impact resulting from the company’s operations.

- Implementing measures to minimize greenhouse gas emissions.

- Utilizing raw materials and products that are environmentally friendly.

As part of the company’s climate change management approach, there has been a reduction in electricity consumption and the utilization of renewable energy through a solar rooftop power generation system installed on the factory roof. This has resulted in a significant decrease in greenhouse gas emissions, contributing to the sustainable preservation of the environment.

Furthermore, the company recognizes the significance of minimizing its environmental and climate change impact. As part of its efforts, the company has initiated a project to upgrade its painting oven from a convection oven to an infrared oven (IR Oven). This transition allows for energy savings and a reduction in greenhouse gas emissions. The project is currently undergoing performance evaluation.

Goals

The company realizes the importance of climate change and global warming. Risks from climate change affects the company’s business operations. The company therefore places importance on reducing greenhouse gas emissions, in response to government and private sector policies both domestically and internationally that focuses on reducing greenhouse gas emissions. The company has established a working team of carbon footprint management, conducting an assessment of the company’s greenhouse gas emissions. By setting the year 2021 as the base year. There were a data verification process, data storage, and the measure of the amount of greenhouse gas emissions to a standard. In 2023, the company has hired ECEE Company Limited to be a verifier of the organization’s greenhouse gas emissions. This was the information between 1 January 2022 and 31 December 2022. The company was certified Carbon Footprint for Organization from Thailand Greenhouse Gas Management Organization (Public Organization). The company has set goals to reduce greenhouse gas emissions and its result as follows

| Emission scope of greenhouse gases | Base Year | Target Year for Short Term | Target Year for Long Term |

| Scope 1 | 2023: Greenhouse gas emissions 10,428.00 tCO2e | 2024: Reduced 1.88% or 194.13 tCO2e compared to the base year. | – : compared to the base year N/A tCO2e vs base year. |

| Scope 2 | 2023: Greenhouse gas emissions 8,683.00 tCO2e | 2024: Reduced by 0.37% or 35.13 tCO2e compared to the base year. |

1. Direct greenhouse gas emissions (Scope 1):

Caused by the combustion of various fuels, both from machines and from company-owned vehicles such as combustion from the use of LPG, gasoline and diesel, etc. It is also from Carbon dioxide emissions from the production process, use of refrigerants and the use of chemicals in the wastewater treatment system.

2. Indirect greenhouse gas emissions from energy use (Scope 2):

Caused by using the company’s electricity.

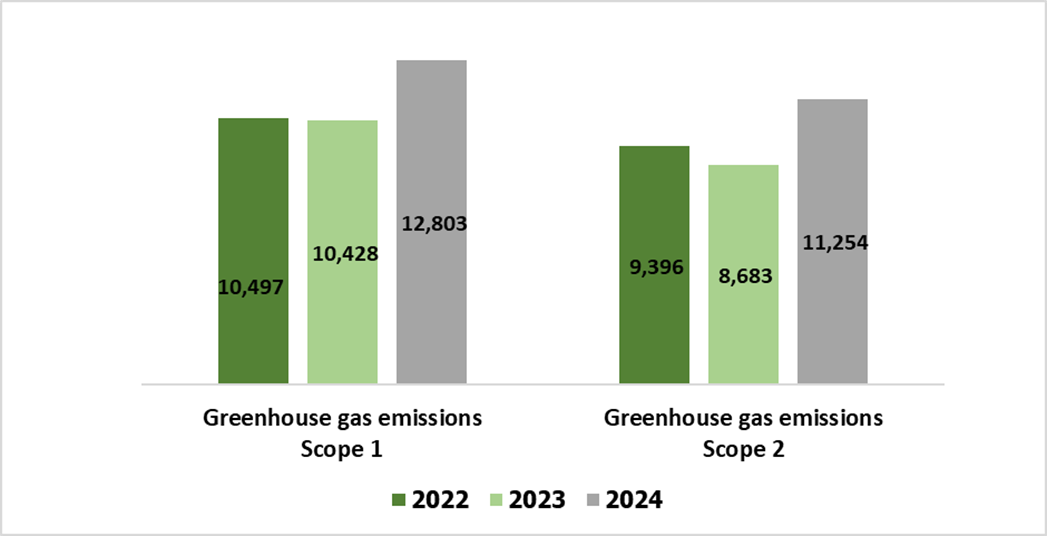

Performance

In 2024, the company has set a goal to reduce greenhouse gas emissions by 2.25 percent compared to 2023. In 2024, the company emitted a total of 24,057 tons of carbon dioxide equivalent or an increase of 25.88 percent compared to 2023, mainly due to increased electricity usage. The company increased in production volume and the additional of machines in the production process. However, the company still committed to continuously reduce greenhouse gas emissions. There are plans to improve machinery in the production process to be more efficient and reduce energy consumption to achieve the goal of reducing greenhouse gas emissions in the future.

Management to Reduce Greenhouse Gas Issues: Greenhouse Gas Emissions of the Organization

| Management to reduce greenhouse gas problems: amount of greenhouse gas emissions | 2022 | 2023 | 2024 |

| Total amount of greenhouse gas emissions (Tons of carbon dioxide equivalent) | 19,893.00 | 19,111.00 | 24,057.00 |

| Greenhouse gas emissions – Scope 1 (Tons of carbon dioxide equivalent) | 10,497.00 | 10,428.00 | 12,803.00 |

| Greenhouse gas emissions – Scope 2 (Tons of carbon dioxide equivalent) | 9,396.00 | 8,683.00 | 11,254.00 |

Types of air pollution

Nitrous Oxide (NOx)

Volatile Oraganic Compounds (VOCs)

Particulate Matter (PM)

Carbon Monoxide (CO)

Sulphur Oxide (SOx)

Hazardous Air Pollutants (HAP)

Performances

The Company does not emit this type of air pollutant.

The Company does not emit this type of air pollutant.